Want your fabrics to feel softer, last longer & perform better? The right silicone softener makes textiles soft, durable and functional in various fabrics.

How to choose a silicone fabric softener for cotton, synthetics, wool & more – by fabric type, desired finish and application methods. Also covered eco-friendly options and silicone-based fabric softener benefits, delivered by Colourinn Auxiliaries – delivering tailored textile solutions for various industries.

Understanding Silicone Softeners

Silicone softener is a textile finishing agent which is based on polysiloxane compounds which cover fibres to confer a good softness, a good slidability and an adequate elasticity.

Unlike the traditional softeners, silicone fabric softener is wear-resistant after multiple wash cycles. These softeners cause less friction between fibres and make fabrics plush and comfortable.

The materials are used for clothing, home textiles and technical fabrics with a premium hand feel and performance.

Why Silicone Softeners Matter

Its Si-O-Si backbone gives silicone-based fabric softener flexibility, thermal stability and lubrication – soft but resilient fabrics. They also provide anti-static properties and, in some cases, water repellency – important properties for textiles of today.

The selection of suitable silicone softener guarantees that your fabrics fulfil the requirements of consumers regarding comfort and durability.

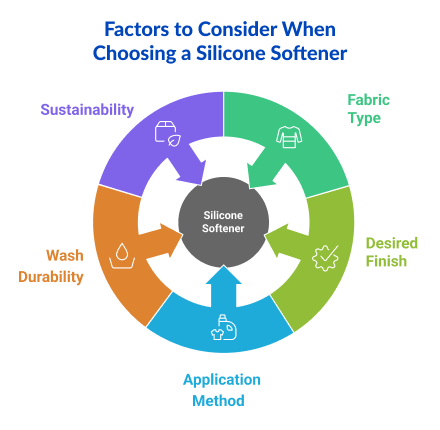

Factors to Consider When Choosing a Silicone Softener

How to choose a silicone softener varies. Knowing these will help you match the softener to your fabric and production goals.

- Fabric Type

Different fabrics need different silicone fabric softener formulations:

- Cotton: Softener made of hydrophilic silicone maintains absorbency while increasing softness of towels and bed sheets.

- Polyester/Nylon: For synthetics, amino or block copolymer softeners impart smoothness and anti-static benefits.

- Wool: Epoxy-modified softeners impart durability without textural degradation.

- Silk: Softeners penetrate into fibres for sheen and breathability.

- Desired Finish

Your finish controls which silicone-based fabric softener to use:

- Soft and Silky: The amino silicones give high-end apparel a soft feel.

- Glossy Sheen: Softeners with block copolymer add lustre to curtains & scarves.

- Matte and Natural: Hydrophilic softeners keep an invisible breathable finish on activewear.

- Application Method

What kind of silicone softener you apply influences how it performs:

- Padding: Assures even distribution for large-scale production.

- Exhaustion: Ideal for very small batches with deep penetration.

- Spraying: Optimal for targeted applications but requires precision to avoid unevenness.

- Wash Durability

For fabrics that will be washed frequently, select a silicone fabric softener having high silicone-based fabric softener durability, such as block copolymers or epoxy-modified types.

- Sustainability

And eco-friendly silicone softener options like bio-based or fluorine-free reduce environmental impact, and meet regulatory requirements such as ZDHC.

Textile finishing is an important process of the textile manufacturing process, to know more about finishing visit: Textile Finishes: Different types of Finishes for Textiles.

| Factor | Consideration | Best Softener Type |

| Fabric Type | Cotton, synthetics, wool, silk | Hydrophilic, amino, epoxy, nano |

| Finish | Silky, glossy, matte | Amino, block copolymer, hydrophilic |

| Application | Padding, exhaustion, spraying | Varies by method |

| Durability | Wash resistance | Block copolymer, epoxy-modified |

| Sustainability | Eco-friendly, biodegradable | Fluorine-free, bio-based |

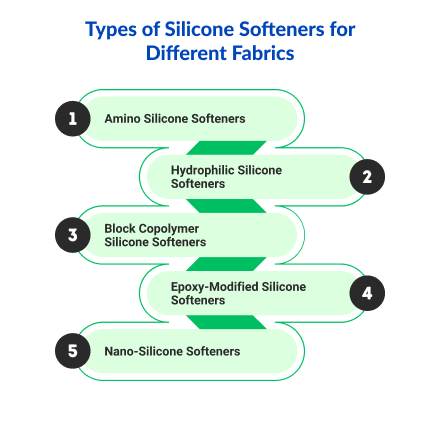

Types of Silicone Softeners for Different Fabrics

Each silicone softener type is for particular fabrics and applications. Here’s a breakdown:

- Amino Silicone Softeners

Amino silicones are the go-to for a plush feel. They bind well with fibres; therefore, they work best on cottons and cotton blends for T-shirts and bed linens. They will yellow at high temperatures but should be avoided with light-colored fabrics.

- Best for: Cotton, cotton blends

- Benefits: Softness is outstanding, and washes well.

- Caution: There is a risk of yellowing on white fabrics.

- Hydrophilic Silicone Softeners

Hydrophilic silicone fabric softener has moisture-wicking and softening properties suitable for activewear and towels made of cotton or polyester. They are softeners for breathability & comfort.

- Best for: Activewear, towels, cotton/synthetic blends

- Benefits: Moisture management, eco-friendly options

- Caution: Slightly higher cost

- Block Copolymer Silicone Softeners

Block copolymer softeners contain silicon and some other polymers that impart elasticity and silicone-based fabric softener durability. These are great for upholstery & sportswear requiring extra softness.

- Best for: Upholstery, sportswear, technical textiles

- Benefits: High durability, stretch recovery

- Caution: Complex application process

- Epoxy-Modified Silicone Softeners

Epoxy-modified softeners are all about durability and a dry feel, and they work best on synthetics such as polyester used in uniforms or automotive fabrics. They resist alkali and shear forces.

- Best for: Industrial textiles, synthetics

- Benefits: Resistance to alkali and dry hands.

- Caution: Less hydrophilic

- Nano-Silicone Softeners

Nano-silicone softeners enter fibres deep to impart internal softness without impairing breathability. They’re suitable for silks or knitted clothes.

- Best for: Silk, knits, high-end apparel

- Benefits: Deep penetration, pilling resistance

- Caution: Requires precise application

Application Tips for Optimal Results

Correct application of a silicon softener yields maximum benefits. Follow these tips:

- Clean Fabrics First: Removing residues like oils or surfactants will not affect softener performance.

- Maintain pH: PH 4-5 promotes absorption. Alkaline conditions can cause emulsion breakdown and sticky rollers.

- Control Dosage: Silicone fabric softener can make fabrics greasy if overused. Follow the manufacturer’s guidelines of 0.5-2% fabric weight.

- Test Compatibility: Check the cationic, non-ionic & anionic nature of the softener against the fabric for good bonding.

Common Mistakes to Avoid

The wrong silicone softeners can yield subpar results. Avoid these pitfalls:

- Ignoring Fabric Type: Amino silicones used on white silk may yellow.

- Overapplication: Excess silicone-based fabric softener makes your fabric greasy and reduces breathability.

- Skipping Tests: Always test compatibility and finish on small-scale trials.

- Neglecting Sustainability: Go for an eco-friendly silicone softener as per modern consumer/regulatory demands.

Colourinn’s Guide to Perfect Silicone Softener Selection

We at Colourinn Auxiliaries understand that the success of the textiles in terms of their “luxurious Touch” & “performance” depends on the right selection of Silicone Softener.

So far, this guide has shown you how to select the right silicone fabric softener for your fabric type, finish, application method and sustainability requirements. From amino silicones for cotton to nano-silicones for silk, with our silicone-based fabric softener solution, you get comfort with durability.

Ready to soften textiles with the ideal silicone softener? Explore new eco-friendly softeners from Colourinn Auxiliaries. See our solutions for softness, durability & customer satisfaction at Colourinn. Create extraordinary textiles with us!

Frequently Asked Questions(FAQs):

Q1. What is a silicone softener and how does it work on fabrics?

A. A silicone softener is a textile finishing agent that improves fabric softness, elasticity, and smoothness. It covers fibers with a thin silicone layer, enhancing the hand feel without compromising breathability or appearance

Q2. Can silicone softener be used on synthetic fabrics like polyester?

A. Yes, silicone softeners are suitable for synthetic fabrics like polyester. It reduces static, improves softness, and adds flexibility, making garments more comfortable and wrinkle-resistant after processing

Q3. How do I apply silicone softener for optimal results?

A. Dilute silicone softener as directed and apply via padding, spraying, or exhaust method. Ensure uniform application, proper drying, and curing for optimal softness, smoothness, and fabric performance