Silicone softener solutions in textiles contribute to fabric comfort, durability and appeal. This article reviews the types of silicone softeners for textiles, namely amino, hydrophilic and block copolymer softeners and their applications in apparel, home textiles and technical fabrics.

We will also discuss their benefits, like improved silicone softener wash durability and eco-friendly innovations. Join us to see how Colourinn Auxiliaries provides solutions for textile excellence.

What Are Silicone Softeners?

A silicone softener coats fabric fibres for softening, smoothing and flexibility. Unlike conventional softeners, silicone softener for textiles with polysiloxane compounds produces a soft handle and imparts durability.

These softeners decrease friction between fibres and fabrics to feel softer and more pliable. They’re used on cotton, polyester, wool, and blends & benefits include wrinkle resistance & silicone softener wash durability.

Why Silicone Softeners Stand Out

Silicone softeners outperform other finishing agents owing to a peculiar chemical structure. Polysiloxanes-Si-O-backbone is particularly flexible, lubricant and thermally stable.

This makes them suitable for making soft fabrics, with good wear resistance and quality after multiple washes. They fit many textile applications from casual wear to high-performance sportswear.

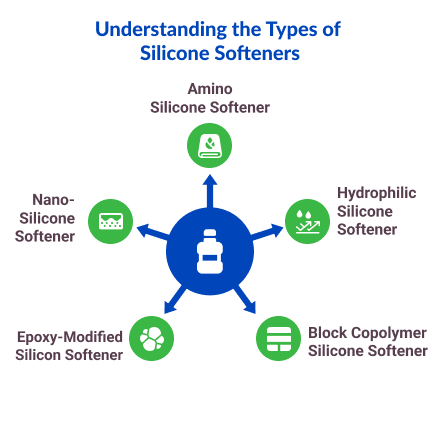

Types of Silicone Softeners

Different silicone softener solutions are used by the textile industry. We review the most common types and their properties below.

- Amino Silicone Softeners

Amino silicone softeners with amino-functional polysiloxanes are the most common ones, due to their exceptional softness. They produce a soft, silky feel on fabrics like cotton and blends – great for apparel and bed linens.

These softeners are in common use for high-class garments, but must not be applied without risk of discoloration. Key features include:

- Softness: Gives a supple feel to the hand.

- Durability: Softens through silicone softener washing cycles.

- Drawback: Amino groups may yellow at high temperatures.

- Hydrophilic Silicone Softeners

Hydrophilic silicone softener for textiles combines softness with moisture-wicking properties.

These softeners absorb moisture into fabrics by adding polyether groups; they are used in activewear and towels. Benefits include:

- Moisture Management: Adds breathability and comfort.

- Versatility: For cotton, synthetics & blends.

- Eco-Friendly Options: Many formulations consider sustainability.

These softeners are gaining traction in sportswear and home textiles for their comfort and performance.

- Block Copolymer Silicone Softeners

Block copolymer softeners combine silicone with another polymer. They form a coating on fabrics, providing lasting comfort.

These are used by manufacturers looking for tough, high-performance finishes. Key advantages:

- Longevity: Resists washing & wear.

- Breathability: Maintains fabric airflow.

- Applications: Suitable for upholstery, activewear and technical textiles.

- Epoxy-Modified Silicone Softeners

Epoxy-modified softeners are tough and dry-feeling, often used in synthetic fibres. These have a crisp hand feel and resist breaking down during washing, but are less hydrophilic. They’re best for:

- Industrial Textiles: Uniforms & automotive fabrics.

- Stability: Resistance to alkali and shear forces is high.

- Nano-Silicone Softeners

Nano-silicone softeners work with particles that penetrate deep into the fabric fibers to provide internal softness without influencing breathability.

Their clear emulsions have no colour change and are good for delicate fabrics. Features include:

- Deep Penetration: Enhances internal softness.

- Pilling Resistance: Improves fabric durability.

- Applications: Knitted fabrics and expensive apparel.

| Type | Key Features | Applications | Limitations |

| Amino Silicone | Silky softness, durable | Apparel, bed linens | Yellowing risk |

| Hydrophilic | Moisture-wicking, breathable | Activewear, towels | Higher cost |

| Block Copolymer | Long-lasting, elastic | Upholstery, sportswear | Complex application |

| Epoxy-Modified | Dry feel, alkali-resistant | Industrial textiles | Less hydrophilic |

| Nano-Silicone | Deep penetration, pilling resistance | Knitted fabrics | Requires precise application |

Applications in the Textile Industry

Silicone softener solutions impart comfort and/or functional benefits to many textile substrates. Common applications include:

- Apparel: T-shirts, skirts and lingerie have a soft, smooth feel because silicone softener is applied to textiles.

- Home Textiles: Bed sheets & towels & curtains become plush and tough.

- Activewear: Yoga pants and sports bras contain hydrophilic softeners for comfort and moisture management.

- Technical Textiles: Automotive upholstery and medical fabrics use silicone softener wash capabilities.

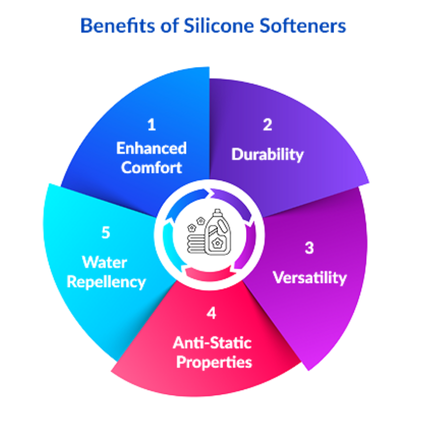

Benefits of Silicone Softeners

A silicone softener gives textiles several advantages:

- Enhanced Comfort: Gives consumer satisfaction a soft, luxurious feel.

- Durability: Qualities are maintained through repeated silicone softener wash cycles.

- Versatility: Compatible with natural and synthetic fibres.

- Anti-Static Properties: Cling & dust attraction are reduced in synthetics.

- Water Repellency: Some formulations make outdoor fabrics hydrophobic

Discover how silicone softeners can elevate fabric quality, boost efficiency, and meet modern textile demands. Visit blog on 10 Benefits of Silicone Softeners in the Textile Industry.

Challenges and Considerations

While silicone softener offers significant benefits, it also contain some challenges:

- Yellowing: The amino silicones may yellow when heated and must be cured.

- Environmental Impact: Traditional formulations might not be biodegradable, so alternatives are sought.

- Application Precision: Overuse might make textures greasy or decrease breathability.

So manufacturers have to compromise performance for sustainability – they have to use eco-efficient formulations to meet regulatory and consumer demands.

How to Apply Silicone Softeners

Silicone softener application must be precise. Common methods include:

- Padding: Fabrics are dipped in a softener emulsion and pressed to distribute evenly.

- Exhaustion: Softeners dissolve in a bath and are good for small batches.

- Spraying: Suitable for targeted applications but less uniform in appearance.

A pH 4-5 increases absorption of softeners, and fabrics must have no residues.

Future Trends in Silicone Softeners

The silicone softener market is undergoing a transition towards sustainability and performance. Key trends include:

- Eco-Friendly Formulations: Softeners that are bio-based and biodegradable have a low environmental impact.

- Multifunctional Softeners: Softness + antibacterial / anti-wrinkle action.

- Nanotechnology: Nano-silicone emulsions permit better penetration and durability.

Colourinn’s Expertise in Silicone Softeners

We at Colourinn Auxiliaries are specialists in silicone softener solutions for textiles. This guide covered all types of silicone softener for textiles from amino to nano-silicone and their applications to produce soft, tough and functional fabrics.

Our new formulations, like nano-silicone emulsions, offer unmatched softness and silicone softener wash durability while being sustainable.

Ready to transform textiles with premium silicone softener solutions? Explore eco-friendly, high-performance softeners from Colourinn Auxiliaries. Find out how ColourInn can give your fabrics comfort, durability and style. Partner with us today to up your textile production!

Frequently Asked Questions(FAQs):

Q1. What is a silicone softener, and why is it used in textiles?

A. Silicone softener is a textile chemical that adds smoothness, elasticity, and a luxurious feel to fabrics. It reduces friction, improves wearability, and enhances fabric drape.

Q2. Which type of silicone softener is best for cotton finishing?

A. Amino silicone softeners are ideal for cotton finishing as they deeply penetrate fibers, improving softness, elasticity, and the fabric’s overall feel and drape.

Q3. How does silicone softener improve fabric quality?

A. It forms a flexible silicone layer on fibers, imparting stiffness reduction, anti-static properties, and softness, acting against breathability, which is required in knits, towels, and performance fabrics.